Sand Lime Core Manufacturing Process

Sand Lime Bricks: A Sustainable Building

2023年6月7日 The manufacturing process of sand lime bricks is easy and straightforward The lime and sand are mixed in a specific proportion and then pressed with the help of a hydraulic press The bricks are then kept in a humid 2024年8月8日 SandLime Brick Production MACHINES PLANTS CONCEPTS The output figures listed in this brochure are guidelines only In practice, the production output depends MACHINES PLANTS CONCEPTS masagroup3 天之前 Sand lime bricks consist of the two raw materials sand and lime only For the manufacturing process, water is required in addition The raw materials that are mostly supplied from local extraction places are stored separately in Sand lime brick production Masa Group2011年11月10日 There are basically 5 steps in the process of manufacturing SandLime Bricks The steps are explained by the flow chart below Figure 3: 5 Steps Manufacturing SandLime Study and Analysis of Fabrication and Properties of Sand

.jpg)

SandLime Bricks and Blocks Technology

During the curing process, the lime reacts with the silica in the sand to form a strong, durable, and fireresistant brick Sandlime bricks are known for their excellent thermal insulation properties, making them ideal for use in Manufacturing process of calcium silicate bricks: Within the first stage, an appropriate ratio of sand, lime, and pigment is mixed well with 3 to 5% water; the paste is obtained with a moldable density The mixture is moulded into bricks Sand Lime Bricks or Calcium silicate bricksManufacturing of Calcium Silicate Bricks In the first step, suitable proportions of sand, lime and pigment are taken and mixed thoroughly with 3 to 5 % of water Then paste with moldable density obtains The mixture is molded into bricks Calcium Silicate Bricks or Sand Lime Bricks for ColdBox technology is a series casting sand core production process based on a reaction between sand and resins at room temperature, accelerated by a catalyst It has been used for over 50 years and continues to be the main method of The ColdBox process in the production of

.jpg)

Sand Lime Brick: The Complete Guide The Brick Calculator

Sand lime bricks, also known as calcium silicate bricks, are made by combining sand, lime, and water Through a chemical reaction during the highpressure steam curing process known as Manufacture of sandlime bricks LISSMAC has made a detailed study of the manufacture of fitting elements This resulted in increased productivity of the latest generation of sandlime Manufacture of sandlime bricks LISSMAC2024年2月22日 Sand Types: Facing sand, system sand, green sand, dry sand, parting sand, loam sand, core sand, and backing sand Mold Structure: Cope, drag, flask, gating system (pouring basin, sprue, runner, riser) Methods: Hand The 6Step Process of Sand Casting: A Stepby 2018年4月9日 Core blowers force sand into the core box by compressed air at about 100 lb/in 2 They can be used for making all types of small and mediumsized cores The cores produced are very uniform, and high production rates Coremaking: Life of a Casting Reliance Foundry

.jpg)

Sand Core Making Processes Validations and

5 天之前 The sand core making model in FLOW3D CAST optimizes the design of core boxes and establishes robust process conditions This article illustrates how simulation helps optimize the design of core boxes and establishes 2021年7月10日 Core Making is the process of forming temporary sand core structures which facilitates formation of internal cavities in a casting product +91 94 277 74756 +91 98 254 The process has evolved from crafting cores one at a time with skilled hands to production of thousands of cores with automated core shooters while moderating tolerances to Core Making Process Foundry Core VentAlso Read: How Mattress Is Made in Factories Manufacturing Process Explained Fly Ash Brick Manufacturing Process Fly ash brick manufacturing involves the following steps: 1 Mixing the Raw Materials The raw materials, namely fly ash, cement, sand, and water are mixed in a pan mixer or a batching plantHow Are Bricks Made Fly Ash Bricks Manufacturing ProcessThe core element in our premixing system is a Titan intensive mixer or highspeed mixer which gives us the following advantages: The sand lime brick manufacturing process is environmentally friendly because it produces fewer emissions and consumes less energy than traditional brickmaking methods Also, sand lime bricks can be recycled and SandLime Bricks and Blocks Technology

.jpg)

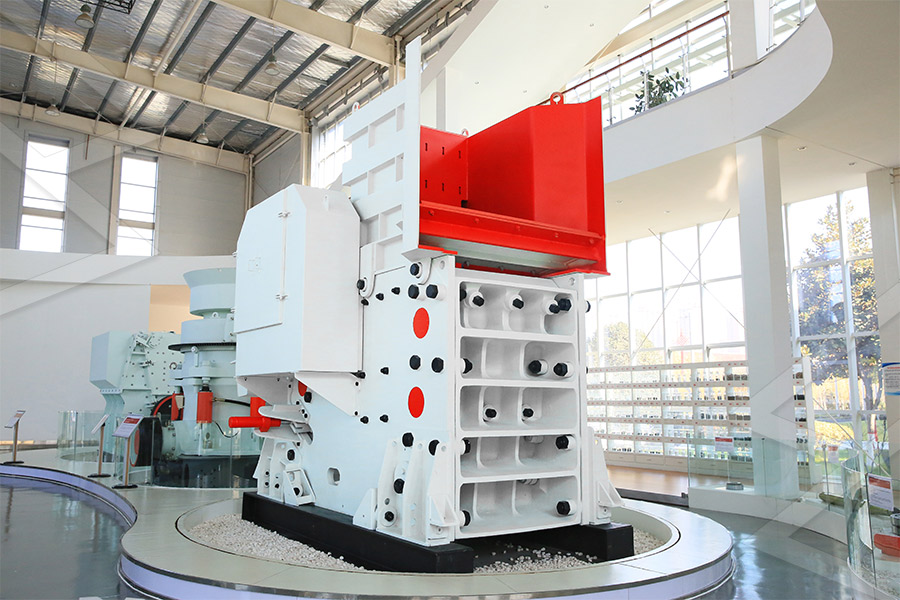

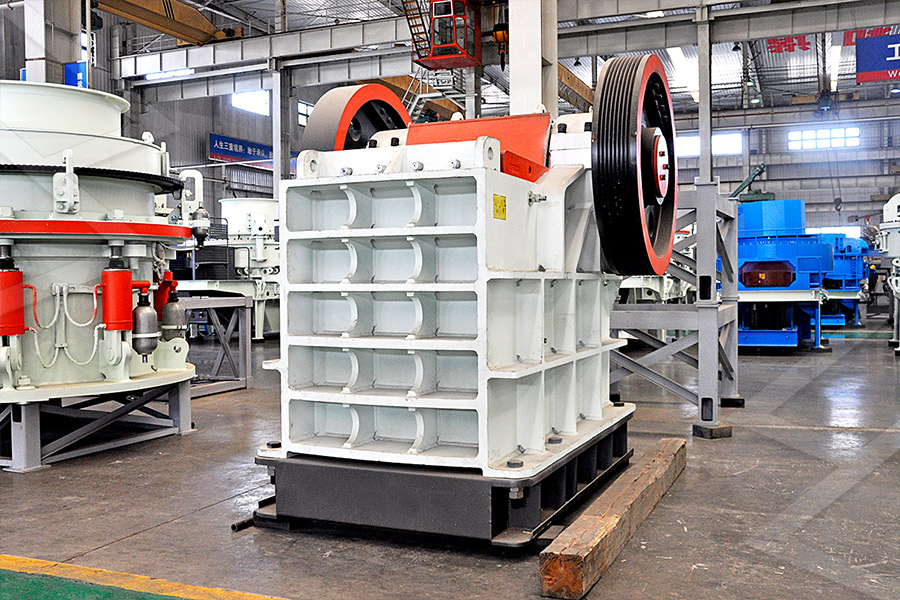

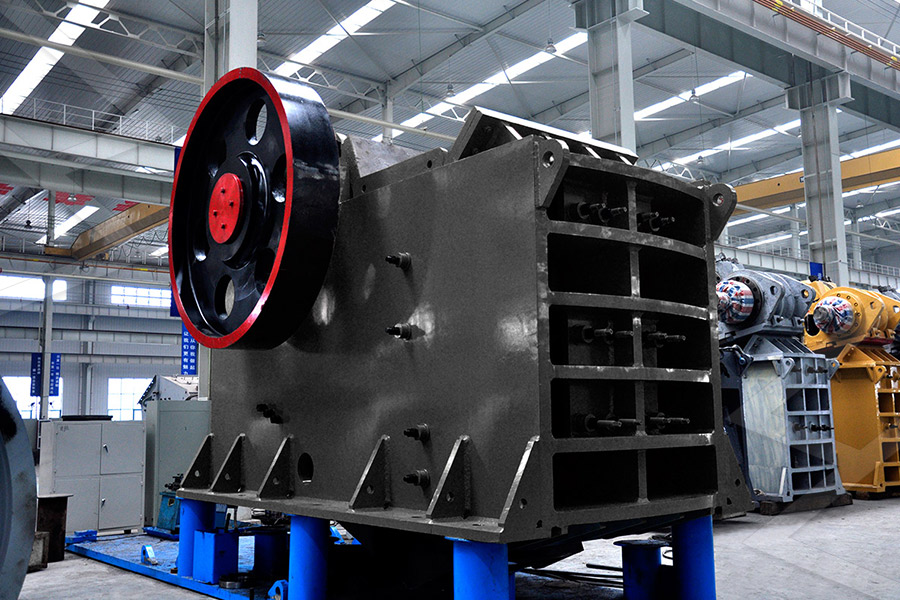

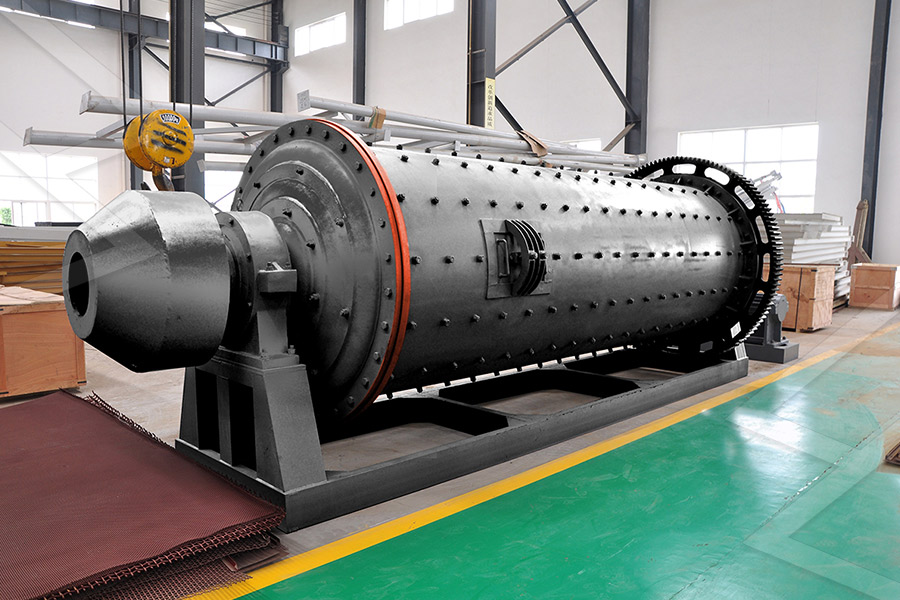

Concrete block production machine XLR Masa Group

2024年10月14日 It's a long way from raw materials through the mixture to the finished sand lime bricks Many plant components are involved in this process Only if the system components are matched, can one be assured of a smooth process and economical operation of the sand lime brick production plant Learn about our Sand lime brick production plants2887, Tianmen Rd, Economic Technological Development Zone, Ma’anshan, Anhui Prov, ChinaPlant Parameters of SandLime Bricks Production Line To 2023年8月15日 The manufacturing process involves the utilization of fly ash, burned clay, coal water, and other relevant materials Volcanic ash is composed of Calcium (Ca), iron, and aluminum silicates When combined with lime and subjected to high temperatures, it undergoes a chemical reaction that results in the formation of pozzolana cementCement: History, Types, Manufacturing Process Science InfoThe quality of the sand core directly affects the quality of the casting during the casting process The establishment of an information link between the sand core and the casting can realize the traceability of sand core production and process data in the casting production The technology can be used when casting defects related to the sand core occur and quickly respond to the Research on a Traceability Process of Sand Core Information

The Sand Lime (Calcium Silicate) Brick Process

Of great interest to structural engineering is the sand lime (calcium silicate) process for the manufacture of bricks, building blocks, tiles, and slabs This has a number of important advantages, including the fact that no skilled labour is Calcination is the core step in the manufacturing process of lime Preheated limestone is fed into the lime kiln, where it is heated at high temperatures to decompose into calcium oxide (lime) and carbon dioxide Throughout the What is the Manufacturing Process of Lime?2024年6月15日 Sand casting is a versatile and widely used method for producing complex metal components, particularly in grey cast iron One of the critical aspects of sand casting is core making, which involves creating the internal cavities and intricate geometries within the castings Advancements in core making techniques have significantly enhanced the quality, precision, Advancements in Core Making Techniques for Sand CastingColdBox technology is a series casting sand core production process based on a reaction between sand and resins at room temperature, accelerated by a catalyst It has been used for over 50 years and continues to be the main method of producing sand cores due to its wide range of applications, efficiency and economic convenienceThe ColdBox process in the production of foundry cores

Types of Core in Sand Casting Mechgrace

2024年10月12日 The dry coremaking process is explained in core making in sand casting article The advantage of using a drystrength core is it has higher strength than a green sand core Dry sand core is free from moisture and reduces defects related to moisture as the dry sand core is dry Dry sand core at times serves as a bottom gate in the gating system2015年1月1日 This process is the only one among all molding and coremaking processes that can use precoated sand, directly available from suppliers and ready for use, although precoating the sand may also be performed at the foundry The sand is cured by heating it in a metallic pattern, producing a hardened surface layerMolds and Cores Systems in Foundry SpringerLink2015年12月25日 Silica sand or quartz sand is a mineral resource with a wide variety of application; glass industry, construction and foundry are the most common examples thereof(PDF) A Life Cycle Assessment of Silica Sand: Comparing the 2023年7月10日 The cement manufacturing process involves the extraction and processing of raw materials, such as limestone, clay, and shale, which are then heated in a kiln at high temperatures to form clinkerCement Manufacturing Process and Its Environmental Impact

.jpg)

Mechanical and durability properties of flyash cement sand

2021年10月12日 Burnt clay brick is one of the most widely used construction materials in developing countries However, the extensive use of burnt clay bricks has resulted in some drawbacks such as the loss of fertile land used for clay extraction and environmental problems associated with unregulated burning processes of brick kilns This study evaluates the Ecofriendly manufacturing process – The manufacturing process of sand lime bricks is ecofriendly, using less energy and producing fewer emissions than other brick types; Easy to work with – Lastly, these bricks are easy to work with, Advantages and Disadvantages of Sand Lime 2019年11月7日 Fly ash or sand, lime, cement, water, and aluminum powder are the main raw materials for producing AAC A total of 3150 kg of mixture (43–45% fly ash or sand, 36–38% water, 13–14% cement, 6–7% lime, and 0025–003% aluminum powder by weight) is prepared for filling a single mold The manufacturing process of AAC blocks is more Manufacturing of Autoclaved Aerated Concrete (AAC): 2020年11月9日 But there were quality problems in the sand blowing process, leading to a spongy sand core that failed repeatedly in the casting process and resulted in a high scrap rate for the cast part Humtown discovered it could Commercializing Sand 3D Printing in the New

Foundry processes: the recovery of green moulding sands for core

2003年6月1日 1 IntroductionCast iron foundries create a large quantity of wastes: onequarter to one ton of solid waste per one ton of casting (EPA, 1981), 30–60% of which is made up of core and moulding sandsThe recovery and reuse of wastes is the alternative with the lowest impact and leads to a saving of raw materials and a reduction of manufacturing residuesThe glass most people are familiar with is sodalime glass, which is a combination of soda (also known as soda ash or washing soda), limestone, and sand Although you can make glass simply by heating and then rapidly cooling silica, the manufacturing of sodalime glass is How Glass is Made What is Glass Made of? Corning2023年11月21日 Glass is an inorganic substance usually made from a combination of sand, soda ash, and lime Sand is composed of silica, or silicon dioxide, and soda ash is composed of sodium carbonate, and lime Glass Production Overview, Types Process Study2023年7月17日 The production of sand cores is a complex process filled with technical challenges that can often times delay production, create scrap and rework, and increase the designs and consider both the core production and casting processes during the design phase of the product development process As a result, the entire process chain Simulation of the entire core production process

Recycled sand for sustainable 3Dprinted sand mold processes

2023年8月25日 Traditional casting methods are losing their appeal due to poor working conditions Integrating additive manufacturing into traditional Casting is a popular solution Among the seven additive manufacturing categories, binder jet 3D printing is most suitable for 3D printing sand molds However, issues like waste management and environmental problems in binder Sand lime bricks, also known as calcium silicate bricks, are made by combining sand, lime, and water Through a chemical reaction during the highpressure steam curing process known as autoclaving, a sturdy, durable brick is formed These bricks are known for their uniform shape, smooth finish, and excellent loadbearing capacity Sand Lime Brick: The Complete Guide The Brick Calculator2020年11月1日 Production of sand core in the PUCB process consists of two steps: shooting and curing In the first step, the sandbinder mixture forms the shape of the cavity in the core box, while during the (PDF) Mold and Core Sands in Metalcasting: Chemistry and 2024年2月22日 Sand Types: Facing sand, system sand, green sand, dry sand, parting sand, loam sand, core sand, and backing sand Mold Structure: Cope, drag, flask, gating system (pouring basin, sprue, runner, riser) Methods: Hand The 6Step Process of Sand Casting: A Stepby

Coremaking: Life of a Casting Reliance Foundry

2018年4月9日 Core blowers force sand into the core box by compressed air at about 100 lb/in 2 They can be used for making all types of small and mediumsized cores The cores produced are very uniform, and high production rates 5 天之前 The sand core making model in FLOW3D CAST optimizes the design of core boxes and establishes robust process conditions This article illustrates how simulation helps optimize the design of core boxes and establishes Sand Core Making Processes Validations and 2021年7月10日 Core Making is the process of forming temporary sand core structures which facilitates formation of internal cavities in a casting product +91 94 277 74756 +91 98 254 The process has evolved from crafting cores one at a time with skilled hands to production of thousands of cores with automated core shooters while moderating tolerances to Core Making Process Foundry Core VentAlso Read: How Mattress Is Made in Factories Manufacturing Process Explained Fly Ash Brick Manufacturing Process Fly ash brick manufacturing involves the following steps: 1 Mixing the Raw Materials The raw materials, namely fly ash, cement, sand, and water are mixed in a pan mixer or a batching plantHow Are Bricks Made Fly Ash Bricks Manufacturing Process

.jpg)

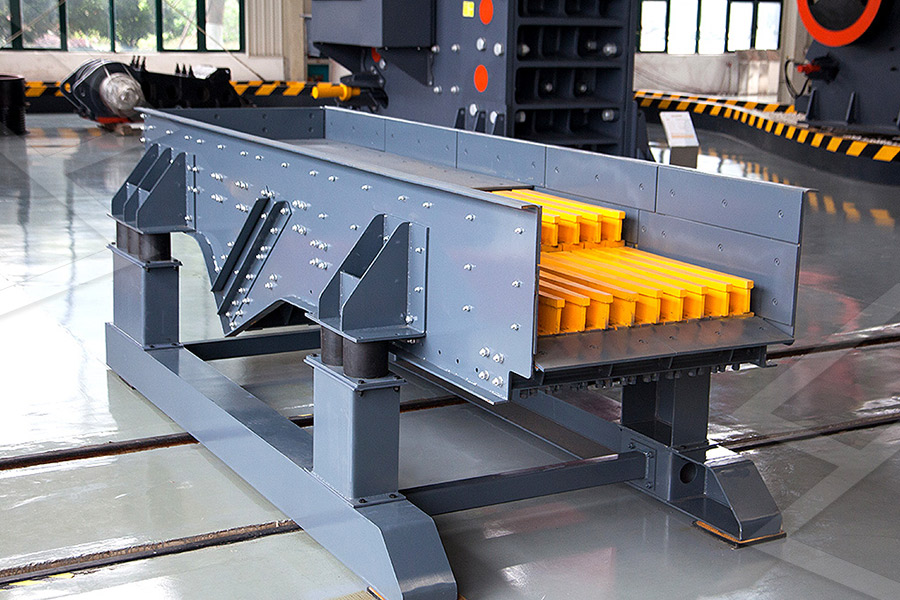

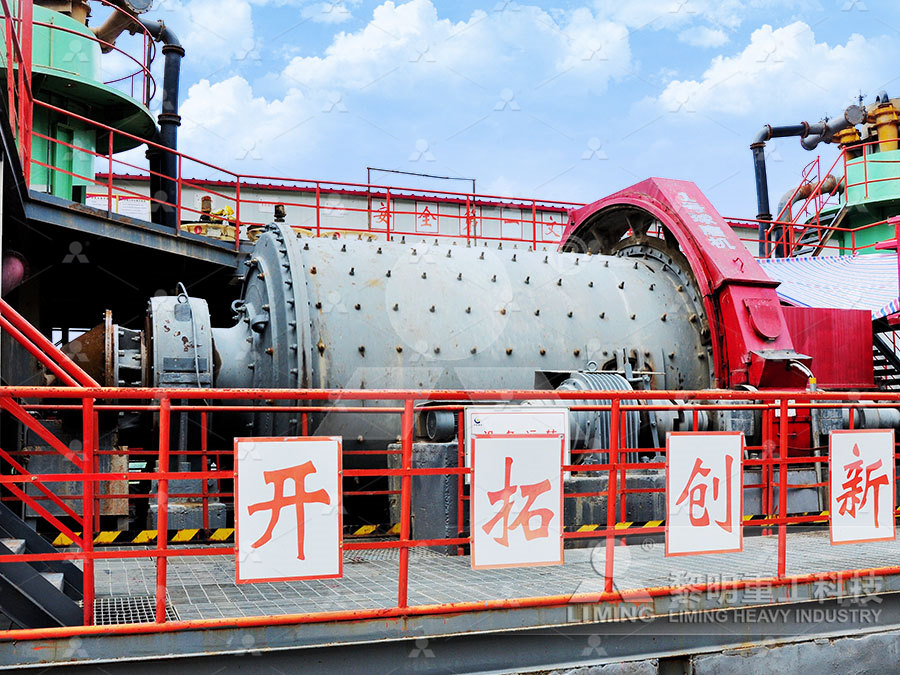

SandLime Bricks and Blocks Technology

The core element in our premixing system is a Titan intensive mixer or highspeed mixer which gives us the following advantages: The sand lime brick manufacturing process is environmentally friendly because it produces fewer emissions and consumes less energy than traditional brickmaking methods Also, sand lime bricks can be recycled and 2024年10月14日 It's a long way from raw materials through the mixture to the finished sand lime bricks Many plant components are involved in this process Only if the system components are matched, can one be assured of a smooth process and economical operation of the sand lime brick production plant Learn about our Sand lime brick production plantsConcrete block production machine XLR Masa Group2887, Tianmen Rd, Economic Technological Development Zone, Ma’anshan, Anhui Prov, ChinaPlant Parameters of SandLime Bricks Production Line To 2023年8月15日 The manufacturing process involves the utilization of fly ash, burned clay, coal water, and other relevant materials Volcanic ash is composed of Calcium (Ca), iron, and aluminum silicates When combined with lime and subjected to high temperatures, it undergoes a chemical reaction that results in the formation of pozzolana cementCement: History, Types, Manufacturing Process Science Info

Research on a Traceability Process of Sand Core Information

The quality of the sand core directly affects the quality of the casting during the casting process The establishment of an information link between the sand core and the casting can realize the traceability of sand core production and process data in the casting production The technology can be used when casting defects related to the sand core occur and quickly respond to the